Description

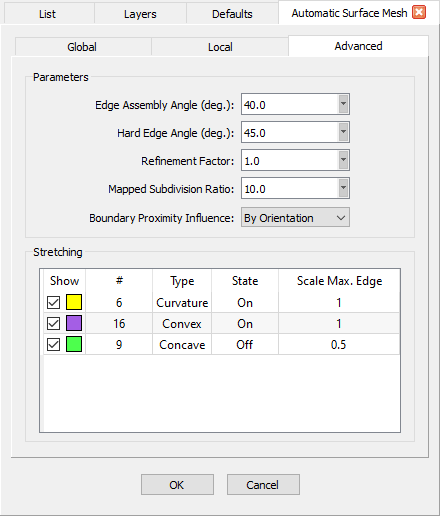

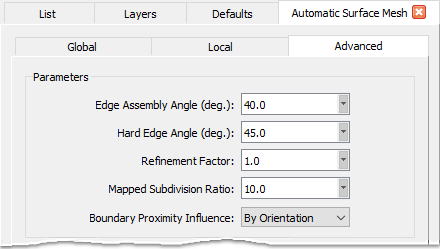

The Advanced panel presents additional advanced parameters to control the

characteristics of the surface mesh to be created, including controls to enable/disable 2D T-Rex

for specific boundary types.

The Advanced panel provides additional, more advanced controls over the characteristics of the

surface mesh being created.

Parameters

The

Parameters frame provides several additional parameters to control the

characteristics of the resulting surface mesh.

The Parameters frame provides additional parameters for identifying hard edges and mappable

surfaces, refining the surface mesh, and determining which boundaries are considered for

domain adaption.

The Edge Assembly Angle parameter is the angle (prescribed in degrees)

used to determine whether or not to join connectors when generating the surface mesh. This

parameter has a default value of 40.0 and a valid range of [0, 180).

Note: Changing the Edge Assembly Angle may affect how

boundaries are reported on the Global tab. For example, if the new

value for Edge Assembly Angle causes the smallest boundary edge to be joined when

connectors are built, Min. Boundary Length in the Geometry

Characteristics frame on the Global tab is updated accordingly.

The Hard Edge Angle parameter is the angle (prescribed in degrees) used

to determine whether the edge between two quilts represents a convex or concave edge. This

parameter has a default value of 45.0 and a valid range of [0, 180). If the angle between

the quilt normals is greater than the prescribed value, the edge is classified as Convex (if

the normals point away from the boundary) or Concave (if the normals point toward

the boundary).

The Refinement Factor parameter is used to globally refine or coarsen

the surface mesh. This parameter has a default value of 1.0 and a valid range of [0.125, 8].

Tip: The Refinement Factor can be used to quickly generate

surface meshes for an entire mesh family. Once you are satisfied with the quality of the

surface mesh, use factors < 1 to generate coarser surface meshes

and factors > 1 to generate finer surface meshes.

The Mapped Subdivision Ratio parameter is used to identify

thin surfaces for special mapped mesh handling (i.e. surfaces for which the unstructured

domain should be mapped to an underlying structured domain). This parameter has a default

value of 10.0 and a valid range of [0, ∞), where a value of 0 disables thin surface

meshing.

The Mapped Subdivision Ratio parameter is used to identify surfaces that are good candidates

for using mapped unstructured domains. The images show the difference between using a mapped

domain (left) and an unmapped domain (right) for the blunt trailing edge of a wing.

The Mapped Subdivision Ratio parameter is defined as the ratio of the subdivisions of the

long and short connectors for unstructured domains defined by four connectors. If the computed

ratio is greater than the defined value, the connector distributions and dimensions are synced

to create a balanced structured domain. The structured domain is then diagonalized with the

Link option enabled using either the Best Fit or Keep Quads

diagonalization methods, depending on the Algorithm setting on the

Global tab. For more information on domain diagonalization, please

review the description of the

Diagonalize command in this User Manual.

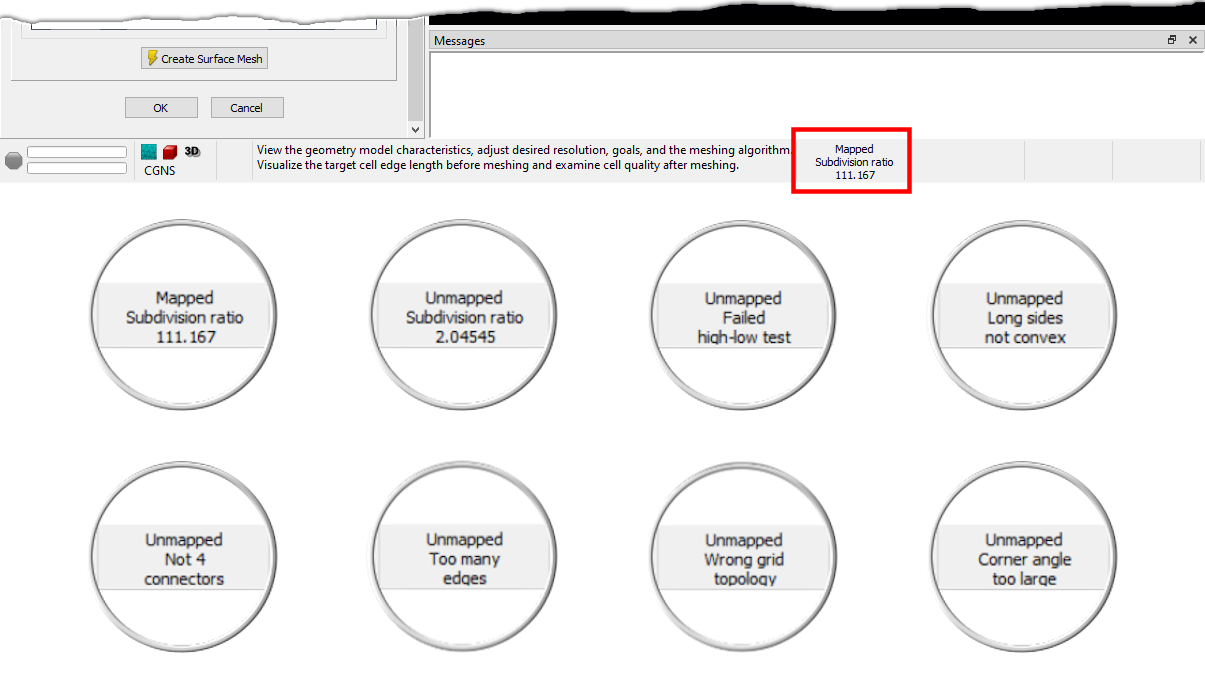

After the Create Surface Mesh command is finished, hovering the mouse over the

domains displays information about whether or not the domain is mapped in the probe area of the

Status Bar. Domains that are mapped

also display the computed subdivision ratio while domains that are unmapped show information

about why it was classified as such. Please click the Mapped Domain Probe Messages

button below to view a table showing the possible probe messages that could be displayed as well as

their meanings.

When you hover over domains while in the Automatic Surface Mesh command, the probe area of the

status bar (red rectangle) displays information about whether or not that domain is mapped. This

image shows a selection of the more common messages. Click on the Mapped Domain Probe Messages

button below to see a complete list of all messages.

The Boundary Proximity Influence parameter controls which connectors

become sources for domain adaption and has three options:

- By Orientation: Only connectors on the outward side of a domain's quilt

are used as sources for domain adaption. This option is useful for preventing undesired

clustering from connectors on the opposite side of the model and is the default option.

- All: All nearby connectors are used as sources for domain adaption.

- None: No connectors are used as sources for domain adaption.

The Boundary Proximity Influence determines which connectors (if any) influence clustering on the

interior of domains. Use the By Orientation option (shown left) to prevent undesired

bleed-through clustering that can sometimes result from using the All option (shown right).

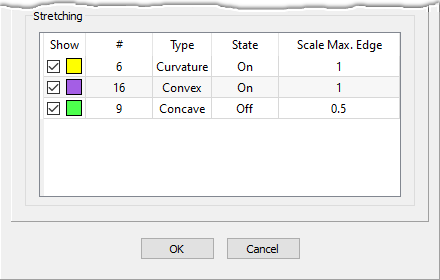

Stretching

The table in the Stretching frame provides controls for viewing, enabling/disabling,

and refining the three different classified boundary types: Curvature, Convex,

and Concave. Edges are classified as Curvature edges if the target

connector dimension based on surface curvature is much greater than the target dimension based

on the curvature of the edge's underlying curve definition (i.e. the edge is straight

but the quilts sharing that edge have significant curvature in the direction normal to the

edge). Connectors created on edges classified as

Curvature are automatically assigned to an Angle T-Rex boundary

condition.

Edges are classified as Convex and Concave according to the

Hard Edge Angle parameter in the Parameters frame above.

Connectors created on edges classified as Convex and Concave are automatically assigned

to a Max. Aspect Ratio T-Rex boundary condition. For more information on 2D T-Rex boundary

conditions, please review the

2D T-Rex Boundary

Conditions page in this User Manual.

The Stretching frame provides tools that allow you to visualize, enable/disable, and adjust

the refinement of the three types of classified boundaries.

The Type and # columns display read-only values showing the name of the

classified boundary type and the number of connectors associated with that type, respectively.

Use the Show column to enable/disable the display of each classified type. By default,

the checkboxes are checked on and the connectors are rendered in the Display window

using the corresponding color in the Show column. Uncheck the checkbox to disable the

display of a classified boundary type.

The State column allows you to specify whether 2D T-Rex is enabled/disabled for a

particular classified boundary type during the creation of the surface mesh. By default,

Curvature and Convex are turned On and Concave is turned

Off. Click in the State field of a row to bring up a drop-down menu that can

be used to toggle the State On or Off.

The Scale Max. Edge column allows you to scale the edge length for a classified

boundary type with respect to the settings on both the Global and

Local tabs. Scale Max. Edge has a valid range of [0, 1] and

the default setting is 1.0 if the State of the boundary type is On and 0.5

if Off.