Description

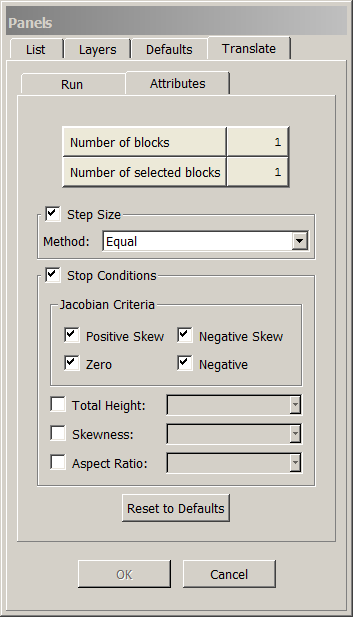

In the Attributes tab for translational extrusion, you have available two main attributes to help control your extrusion: Step Size and Stop Conditions. Both attributes are collapsed by default. Checking a category will expand it and allow you to make changes to those attributes before running your extrusion.

Step Size

In the Step Size frame, you can set up your extrusion to march out based on an equal step size or by specifying a subconnector(s) for the extrusion to march along. The Method pull-down allows you to choose Equal or Subconnector for these two methods respectively.

The Equal method computes the step size by taking the total distance specified for the extrusion and dividing it by the total number of extrusion steps.

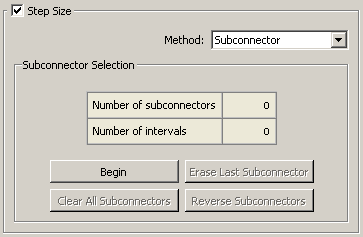

When Subconnector is selected for the step size method, the Subconnector Selection frame becomes available (see figure below). This frame allows you to select the subconnectors you wish the extrusion to follow by selecting the Begin command and to end selection of those subconnectors with the End command. The Erase Last Subconnector command deselects the last subconnector selected whereas the Clear All Subconnectors command deselects all subconnectors. Reversal of the direction of the selected subconnectors is done via the Reverse Subconnectors command.

Stop Conditions

The Stop Conditions are the same for all extrusion types and are described in the Attributes Tab section for the Normal extrusion.